A shortage of ventilators became a worldwide crisis in March 2020 with the arrival of COVID. Within weeks, a volunteer team of clinicians and engineers — many from the UW — committed to developing a low-cost ventilator that could be stockpiled for use in intensive care units but also used in settings with limited resources.

The result is WorldVent, a streamlined ventilator that can be rapidly and easily produced. WorldVent performs the same life-saving function as highly-technical ICU ventilators at a fraction of the cost.

Jason O. Germany, UW associate professor of industrial design, was recruited to the team early on. The ventilator has received several design awards, including top honors in several major international design competitions.

“This project was a great example of how design can tackle really complex problems in an emergency as part of a great interdisciplinary team,” says Germany, chair of the Industrial Design Program in the UW School of Art + Art History + Design. “It was empowering as a designer to feel that I could potentially have an impact on people’s lives.”

Integrating Design at Every Stage

As an industrial designer, Germany has been on teams for other medical devices, but the urgency of the ventilator project was a different experience altogether. Recruited at the end of spring break in April 2020, he started working on the project two days later. For the next few months, the volunteer project consumed his evenings and weekends.

Germany focused on designing the enclosure and interface elements for the device. The challenge was to accommodate technical and clinical requirements for the ventilator while also considering storage, transportation, and other factors. He communicated regularly with both the engineering and medical teams.

“Part of the designer’s job is to really understand the needs of end users — in this case, medical staff and patients — but also other stakeholders in the design process, including the engineers,” says Germany. “The great thing was that this team knew early on that they needed industrial design help. That says a lot about the people I was working with, that they already valued design and knew it was important to integrate that into the process early.”

While Germany worked to improve the user experience, the engineering team fine-tuned the technology. Sometimes an engineering solution required reworking the design. Other times, a design improvement necessitated changes to the technology architecture. Frequent updates with team members were essential for coordination.

“The team would connect at the end of every day,” Germany recalls. “We met (online) every single day, Saturdays and Sundays included, until sometime in July. It was seven days a week for months.”

10

African nations

have no ventilators

Reaching Low-Resource Communities

While engineers and clinicians developed the ventilator, a GoFundMe campaign raised $40,000 to help cover initial expenses, including the purchase of software licenses and materials for prototypes. Additional funding arrived through the US Army’s xTech: COVID-19 Ventilator Challenge, a competition to help fund ventilator solutions. From hundreds of entries, WorldVent was one of five projects selected, receiving a $100,000 prize.

By autumn 2020, the WorldVent team had a final design and working units from the manufacturer. The ventilator has since received emergency approval from the FDA, similar to emergency approval of COVID vaccines.

It was empowering as a designer to feel that I could potentially have an impact on people’s lives.

As COVID treatments have progressed, ventilators are being used less frequently, making the worldwide shortage less pressing. Still, WorldVent remains an appealing option for hospitals, easily stockpiled for future emergencies. It also shows promise in regions that have neither the funding nor infrastructure for traditional ventilators. The WorldVent team is currently identifying new markets for the product.

“One thing this pandemic highlighted is that some developing nations and low-resource communities have very limited access to medical devices in general,” says Germany. “Ten countries in Africa have no ventilators at all. Part of our mission evolved into looking at those communities. This project was borne out of a pandemic, but it also allowed us to realize that there are communities that we can help, communities that need low-cost ventilators even when this pandemic goes away.”

When Germany joined the WorldVent team, he could not have imagined the trajectory the project — or the pandemic — would take over the next year, or the recognition his work would receive. In June 2021, WorldVent earned second place in the commercial equipment design category of Core77’s international design competition. This month, the Industrial Designers Society of America selected the project for its top design excellence award — a gold award — in commercial industrial design.

The accolades are appreciated, says Germany, but the real reward has been the opportunity to work with such talented and dedicated team members, many of whom are UW researchers and clinicians.

“We had some of the best people in the world poised to respond to this challenge and willing to volunteer their time,” says Germany. “It’s cool that the University of Washington has developed a research community like that. With the enormous amount of expertise at the UW, we were positioned really well to respond to something like this.”

More Stories

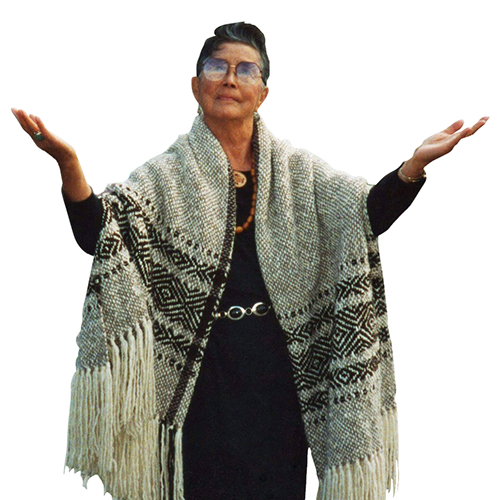

A Healing Heart Returns

In February, the UW Symphony will perform a symphony that Coast Salish elder Vi Hilbert commissioned years ago to heal the world after the heartbreak of 9/11. The symphony was first performed by the Seattle Symphony in 2006.

The Public Impact of Private Cities

Geography major Edwin Bai has researched private cities, developed by individuals and corporations, that "take the libertarian idea of low government regulation to the maximum."

A "gesture" to jump-start careers

To prepare students for professional success, the UW College of Arts and Sciences offers “gesture,” a mock startup company where student interns gain skills that employers seek.